关于先锋

Company Profile

Tubular Membrane Product Series

Keywords:

Tubular Membrane Product Series

Tubular Membrane Product Series details

Introduction to Tubular Membrane

Features

●Anti pollution and anti grease; Not easily clogged and easy to clean;

●Capable of operating at high pressure and flow rate with high throughput and stable operating flux;

●Compared to hollow fiber membrane technology, there is no phenomenon of wire breakage or hardening.Effectively protecting the stable operation of subsequent deep treatment processes;

●Short process flow, small footprint, and saving on civil engineering;

●The system has low total energy consumption, low operating costs, simple operation, convenient

maintenance, and can complete integrated data processing and online monitoring, reducing labor intensity;

●Over 5 years of service life

Tubular membrane refers to the membrane filament with an inner diameter of 1-25 mm and a length of 0.3-6 m,It is formed by casting on a support such as glass fiber synthetic paper,non-woven fabric,plastic,ceramic or stainless steel.Cylindrical membrane.

Hypuron series tubular membrane modules can be applied to seawater desalination pretreatment,chemical dissolved salt water filtration,fruit juice and soy sauce filtration,filtration and separation of high-salt,high-temperature or high-viscosity liquids,landfill leachate treatment,municipal sewage treatment and difficult sewage treatment,etc.industry,and the application market is broad.

Tubular Membrane Series Membrane Components

Technical parameters of HPRG series membrane

| Serial number | Project | Parameter | ||||||||||

| 1 | Membrane form | Internal pressure tubular membrane | ||||||||||

| 2 | Membrane material | PTFE PVDF PES | ||||||||||

| 3 | Shell material | CPVC/FRP | ||||||||||

| 4 | Nominal membrane pore size | 0.03μm/0.1μm | ||||||||||

| 5 | Membrane inner diameter | 6mm78mm | ||||||||||

| 6 | Pure water permeability(25C) | ≥700 L/(m.h.bar) | ||||||||||

| 7 | Expected product water turbidity | ≤1NTU | ||||||||||

| 8 | Maximum water inlet pressure | 1MPa | ||||||||||

| 9 | Produce water SDI | ≤3 | ||||||||||

| 10 | RHrange | 2-11(When cleaning1~12 | ||||||||||

| 11 | Maximum Inhuent Sludge Concentration | 20g/L | ||||||||||

| 12 | Filtration tlux range | 40~200LMH | ||||||||||

| 13 | Maximum Infuent Sludge Concentration | 100Kpa | ||||||||||

| 14 | Maximum operating temperature | 65℃ | ||||||||||

| 15 | Cleaning agent maximum residual chlorine concentration | 250g/L | ||||||||||

| 16 | Operation mode | Airlift filtration or cross-flow filtration | ||||||||||

HPRG series membrane components

Size Chart Of HPRG Series Membrane Module

| Serjal number |

Item | HPRG0203 | HPRG0408 | HPRG0810 | HPRG0814 | HPRG1010 | HPRG1014 | ||||

| 1 | Membrane outer diameter(inch) | 2” | 4” | 6” | 8” | 8” | 10” | 10” | |||

| 2 | Water outlet height A(mm | 80 | 100 | 125 | 170 | 170 | 200 | 200 | |||

| 3 | Water outlet center distance B(mm) | 60 | 60 | 90 | 90 | 90 | 120 | 120 | |||

| 4 | Component height L(mm) | 1000 | 2000 | 3000 | 3000 | 4000 | 3000 | 4000 | |||

| 5 | Component diameter D(mm) | 60 | 108 | 160 | 225 | 225 | 280 | 280 | |||

| 6 | Component diameter R (mm) | 76 | 115 | 150 | 230 | 230 | 300 | 300 | |||

| 7 | Product water interface specification P | DN25 | DN32 | DN40 | DN65 | DN65 | DN65 | DN65 | |||

| 8 | Membrane inner pore diameter(mm) | 8 | 8 | 8 | 8 | 8 | 8 | 8 | |||

| 9 | Produced water interface form | socket union | card socket | ||||||||

| 10 | Membrane tube number(one piece) | 19 | 85 | 197 | 365 | 365 | 469 | 469 | |||

| 11 | Filling area(m) | 0.5 | 4.3 | 14.8 | 27.4 | 36.5 | 35.2 | 46.9 | |||

| 12 | Cross flow flux(LMH) | 40~200 | 40~200 | 40~200 | 40~200 | 40~200 | 40~200 | 40~200 | |||

| 13 | Air lift throughput (LMH) | 40~150 | 40~150 | 40~150 | 40~150 | 40~150 | 40~150 | 40~150 | |||

| 14 | Circulating water flow rate(m/s) | 4~6 | 4~6 | 4~6 | 4~6 | 4~6 | 4~6 | 4~6 | |||

| 15 | Circulating water flow(m³/h) | 14 | 62 | 143 | 264 | 264 | 339 | 339 | |||

| 16 | Series pressure loss(m/one piece) | 4 | 6 | 8 | 10 | 12 | 10 | 12 | |||

| 17 | Air lift water flow rate(m/s | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |||

| 18 | Air lift gas flow rate(m/s) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |||

| 19 | Air lift water volume(m³/h) | 2 | 8 | 18 | 33 | 33 | 42 | 42 | |||

| 20 | Air lift air volume(m³/h) | 2 | 8 | 18 | 33 | 33 | 42 | 42 | |||

| 21 | Dperating pressure(KPa | -50~600 | -50~60 | -50~600 | -50~1000 | -50~1000 | -50~1000 | 50~1000 | |||

| 22 | Operating temperature(C) | 5~65 | 5~65 | 5~65 | 5~65 | 5~65 | 5~65 | 5~65 | |||

| 23 | Applicable PH | 2~12 | 2~12 | 2~12 | 1~13 | 1~13 | 1~13 | 1~13 | |||

| 24 | Membrane material | CPVC | CPVC | CPVC | CPVC/FRP | CPVC/FRP | CPVC/FRP | CPVC/FRP | |||

| 25 | Packaging material | Polyurethane resin | |||||||||

Technique Introduction

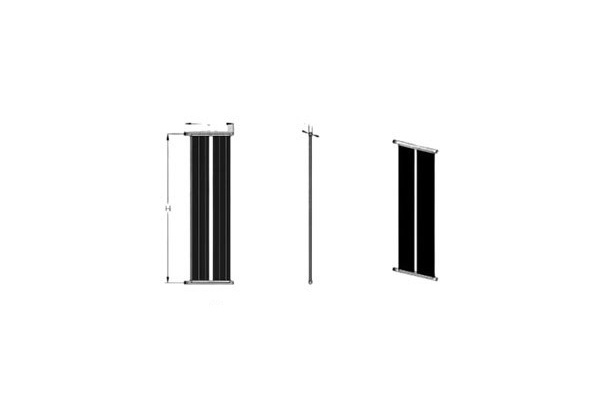

HPRG series membrane module-air lift type

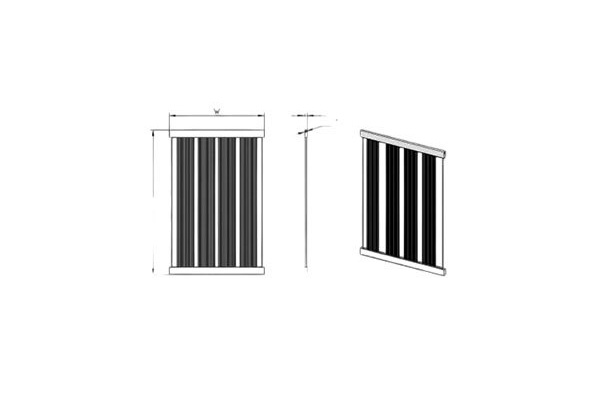

HPRG series membrane components-cross flow type

Product inquiry

Related Products

Address: No. 114 North Ring West Road, Hede Technology Entrepreneurship Park, Sheyang County, Yancheng CityAddress: 14th Floor, Building B2, No. 34 Dazhou Road, YuhuataiDistrict, Nanjing City

Tel: (025) 5883 3306,(0515) 8230 6456

Email: haipurun@hypuron.com

Website: www.hypuron.com

Follow us